A dead battery is inconvenient. A damaged engine control unit (ECU) from a rough jump-start is expensive. Modern vehicles have sensitive electronics, and small errors during a boost can create voltage spikes that travel through control modules and sensors.

Use this guide to avoid the high-risk mistakes and start the car safely in Columbia’s winter or summer heat.

Why Arcing Hurts Electronics

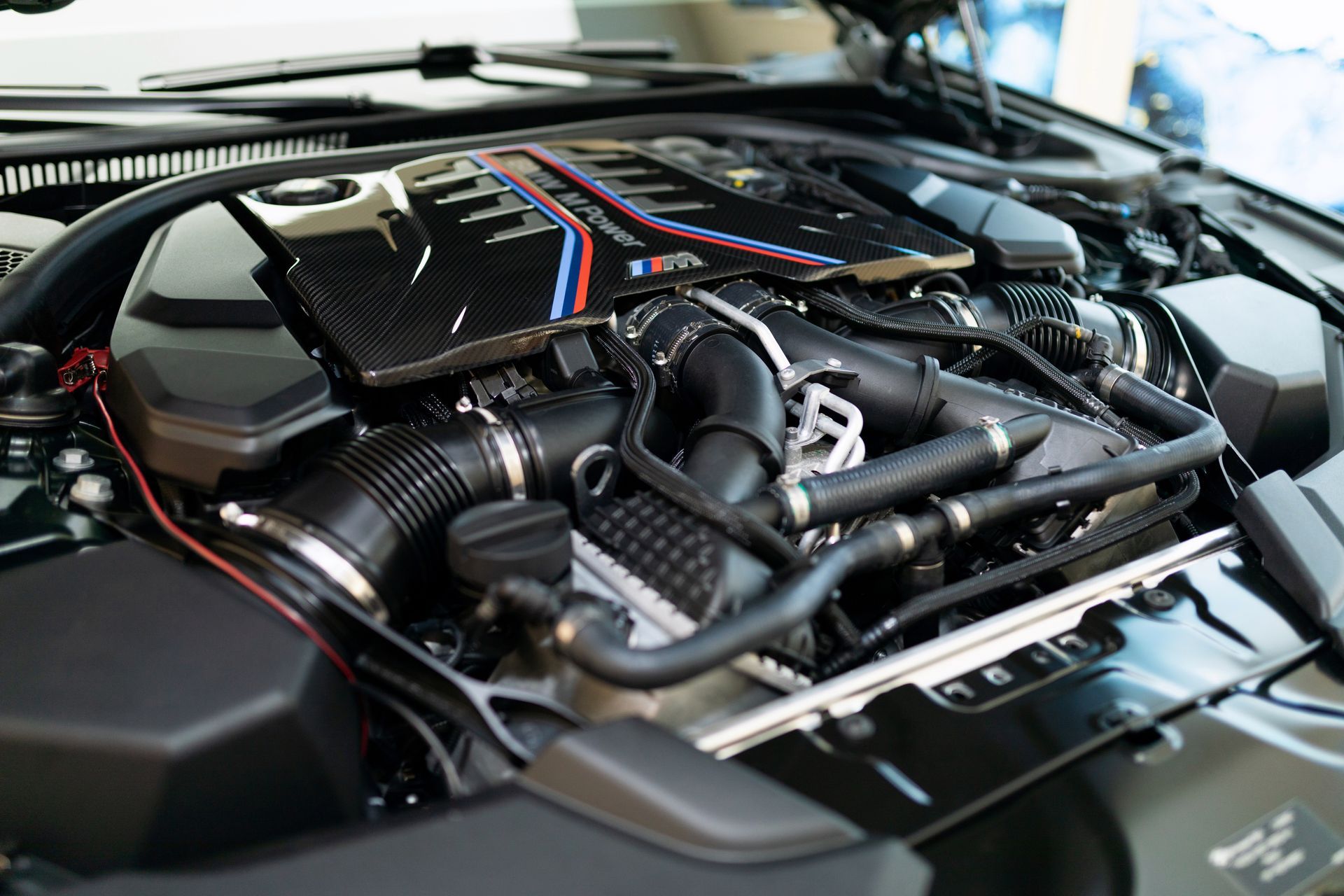

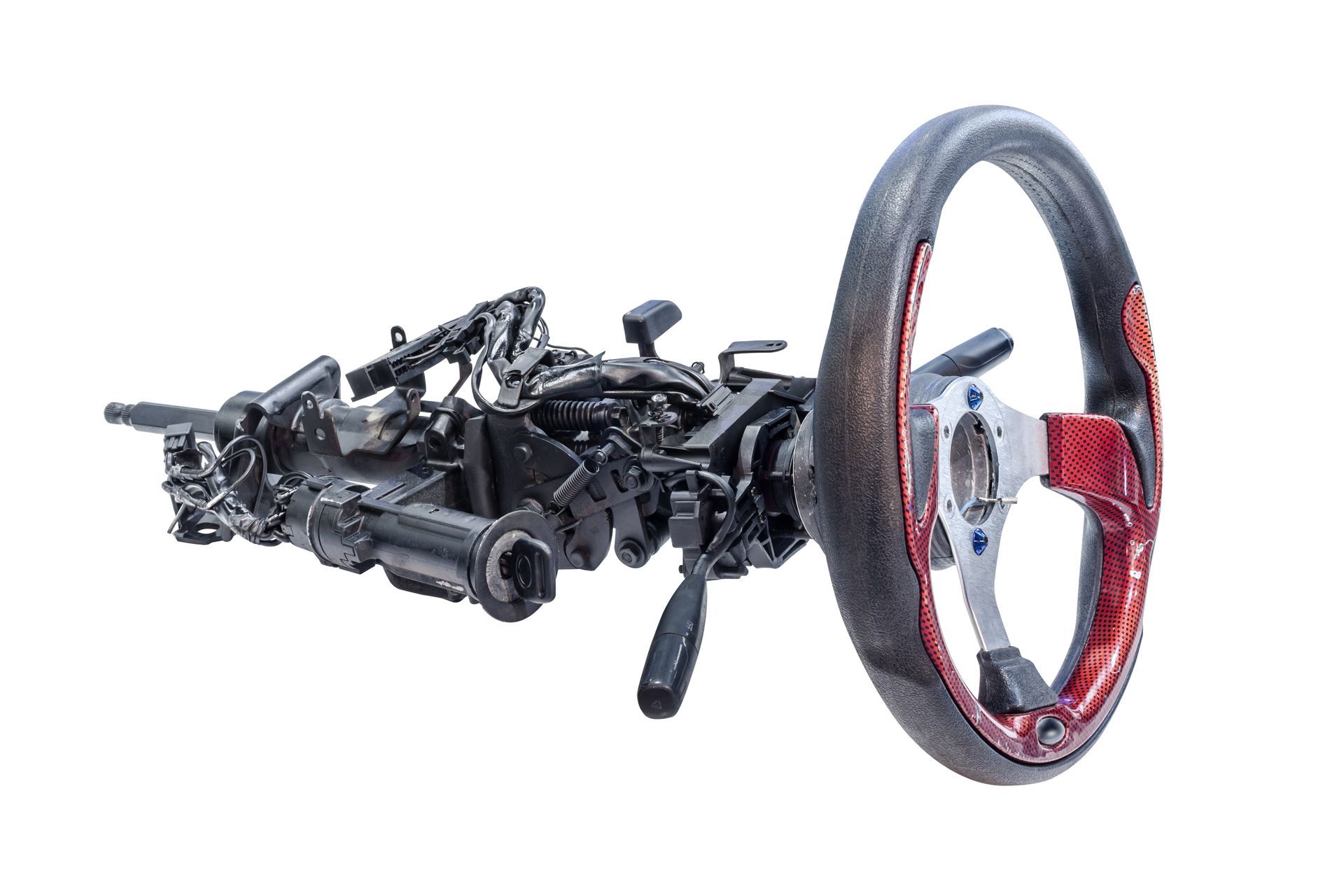

An arc is a rapid on-off connection that produces sharp voltage transients. Every time the clamp slips or bites into paint before finding bare metal, the system sees a spike. ECUs, alternators, electric power steering modules, and infotainment units are all connected to the same bus.

A single arc can pit relay contacts and overload diodes. When we diagnose spike damage, the trail often begins with a scorched clamp mark or a story about “the cables slipped.”

Mistake 1: Reversing Polarity, Even Briefly

Crossing positive and negative is the fastest way to blow fuses and stress modules. Even a split second can trigger a chain of faults.

How to avoid it:

- Identify the positive post first and confirm markings on both vehicles.

- Use remote jump posts if your car has them.

- Connect positive to positive, then connect the negative cable to a solid engine or chassis ground on the disabled vehicle, not to the battery’s negative terminal if there is an intelligent battery sensor.

Mistake 2: Clamping on Paint, Plastic, or Corrosion

A clamp on painted brackets, powder coat, or corroded hardware creates resistance. Resistance causes heat, then arcing, then spikes.

Better approach:

- Scrub to clean, bare metal on a thick bracket or engine lift point.

- Seat the whole jaw of the clamp so it cannot twist free while cranking.

- Keep clamps from touching each other or spinning into belts and fans.

Mistake 3: Revving the Donor Vehicle Hard

Revving “to add juice” can lift alternator voltage and introduce ripple into the disabled car. Some low-quality boosters also lack surge protection.

Safer method:

- Leave the donor at normal idle.

- If using a jump pack, choose one with over-voltage and reverse-polarity protection.

- Pre-charge the dead battery for 2–5 minutes with accessories off before cranking to reduce the initial current spike.

Mistake 4: Disconnecting Cables Immediately After Start

Pulling clamps as soon as the engine catches can cause a sudden load change. That jolt may spike voltage and stress alternator diodes.

Do this instead:

- Let the engine idle for about a minute with cables attached.

- Turn on a small electrical load, like the rear defogger, to stabilize voltage.

- Remove cables in reverse order: ground off first, then positive.

Smart Sequence For a Safe Jump

- Park close but not touching. Set the parking brakes and switch everything off.

- Connect red to the disabled vehicle’s positive, then red to the donor positive.

- Connect black to the donor negative, then black to a clean ground on the disabled vehicle.

- Start the donor and idle. Wait a few minutes.

- Crank the disabled engine up to 10 seconds at a time, resting 30 seconds between attempts.

- Once running, idle one minute, then remove cables in reverse.

- Drive 20–30 minutes or test the battery and charging system soon after.

When To Stop Trying And Call For Help

Stop immediately if cables smoke, the battery hisses, or the case grows warm to the touch. Quit after three failed crank attempts. Repeated attempts can damage the cables, harm the donor alternator, and introduce harmful spikes into the ECU. Our technicians prefer a controlled charge and test over repeated random boosts when symptoms look severe.

Small Habits That Prevent Future Jump-Starts

- Test batteries annually after they pass the three-year mark.

- Keep terminals clean and protect major grounds from rust.

- Replace aging accessory belts so alternators spin at the correct speed.

- Carry a quality booster with surge protection and keep it charged.

Get Professional Battery and ECU-Safe Jump-Start Help in Columbia with Team One Suddeth Automotive

If jump-starts keep failing, or warning lights appear after a boost, visit our Columbia, SC, shop. We can load-test the battery, check alternator ripple, inspect grounds, and scan modules to confirm nothing was stressed. We use regulated boosters and correct grounding points so the car starts without risking the electronics.

Schedule a diagnostic and leave with reliable starts and a clean dash.